Building inspections with heat cameras

Detecting construction deficinecies and quality control

The heat camera inspection is a quick and effective method to find any possible construction deficiencies. Furthermore, it is a great way for quality control and checking construction regulation compliances. Any possible energy losses, moisture and air insulation deficiencies can be detected on the heat image. Futhermore, any heat insulation and construction deficiencies may be identified - without demolition!

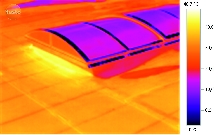

Determinating any leakages in the roof with pinpoint accuracy

Inspecting the leakage points of flat roofs is among the other possible applications of the heat camera. Wet roof areas store the heat of sunlight for a longer time compared to intact areas, resulting in an uneven cooling of the roof during nighttime. The resulting heat difference allows the camera to show the roof areas with moisture or insulation problems.

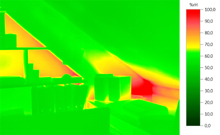

Detailed energy consultation

Infrared measurement techniques are perfect methods to quickly and effectively detect any energy losses in the heating and air conditioning systems. Due to the high thermic sensitivity of the heat cameras, they are able to pinpoint any deficient insulations, thermal bridges and construction faults. Perfectly suitable for the documentation of energy losses developed on windows, doors, heaters, roof structures or on the insulation of buildings. Utilize the opportunities offered by the heat camera in diagnostics, maintenance procedures or energy consulting.

Inspecting damages caused by moisture

Moisture in walls are not always caused by leaking plumbing. Water leaking up or in through the walls can be result of the mis-construction of gutters or drainpipes. Obstructed sinkers and filters can also cause damages. By using the heat camera, causes of floor damp or rain leaks can be detected before water could cause bigger damages.

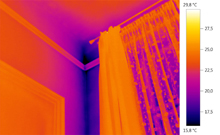

Preventing moldiness

Cold bridges are true "energy-eaters". On these sites air moisture condensation can be expected. As a consequence, it could result fungal coverage that can risk the habitants' health. Heat camera provides important data for allergic fungal coverage prevention, and for the reduction of this risk - even in the most distant part of the house.

Checking air tightness

If doors and windows are not built in correctly, cold air leaks in in the Winter and interior warm air escapes. Consequences: air-blast, increased heat losses when airing, and high energy costs. The combination of thermography and Blower-Door technology is a good way for measuring air tightness. Blower-Door method creates low inside pressure in the building, so cold air can flow in along unsealed joints and flaws. Detecting unsealed parts is much easier with heat camera, therefore unsealed insulations can be repaired before dismantling the finished covers and appliance systems of the new house would be necessary. Otherwise troubleshooting would cost much more.

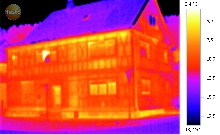

Insulation surveying of buildings

Thermographic examination of large buildings is a real challenge for the user. Spacial limits may arise because of walls, corridors and neighboring buildings, so making one single record for the assessment is not possible. Heat camera helps general examination. Panoramic view wizard helps analyzing and documenting the whole image by putting together several smaller image. There is no need for separate administration, since it automatically displays and compares the images, so heat loss can be visualized in the whole complex.